Why Choose an x86 SBC for Your Next Embedded Computing Project?

Jan 10, 2025

When embarking on an embedded computing project, selecting the right hardware platform is crucial for ensuring smoothly operate. One option that has gained significant traction in recent years is the x86 Single Board Computer (SBC). But why should you consider an x86 SBC for your next embedded computing endeavor? Let's delve into the reasons that make x86 SBCs a compelling choice.

x86 is a Complex Instruction Set Computing (CISC) architecture that is the basis for most PC and laptop computers. x86 Single Board Computer(SBC) is a computer system that installs microprocessors, memory, interface components, etc. on the same printed circuit board. It is often used in applications that require compact, cost-effective solutions, such as education, hobbies, small projects, etc. While ARM SBC is a Reduced Instruction Set Computing (RISC) architecture Motherboard that is the basis for most smartphones and tablets.

- High performance: x86 SBCs usually have high clock speeds and powerful multi-instruction execution capabilities, suitable for tasks that require high computing power, such as video editing, 3D modeling, or running complex simulations.

- Software compatibility: It can run almost all desktop or server software, including Windows, Linux, and macOS.

- Multiple sizes and configurations: There are multiple sizes and configurations, allowing flexible configuration in different applications,such as Mini PC motherboards.

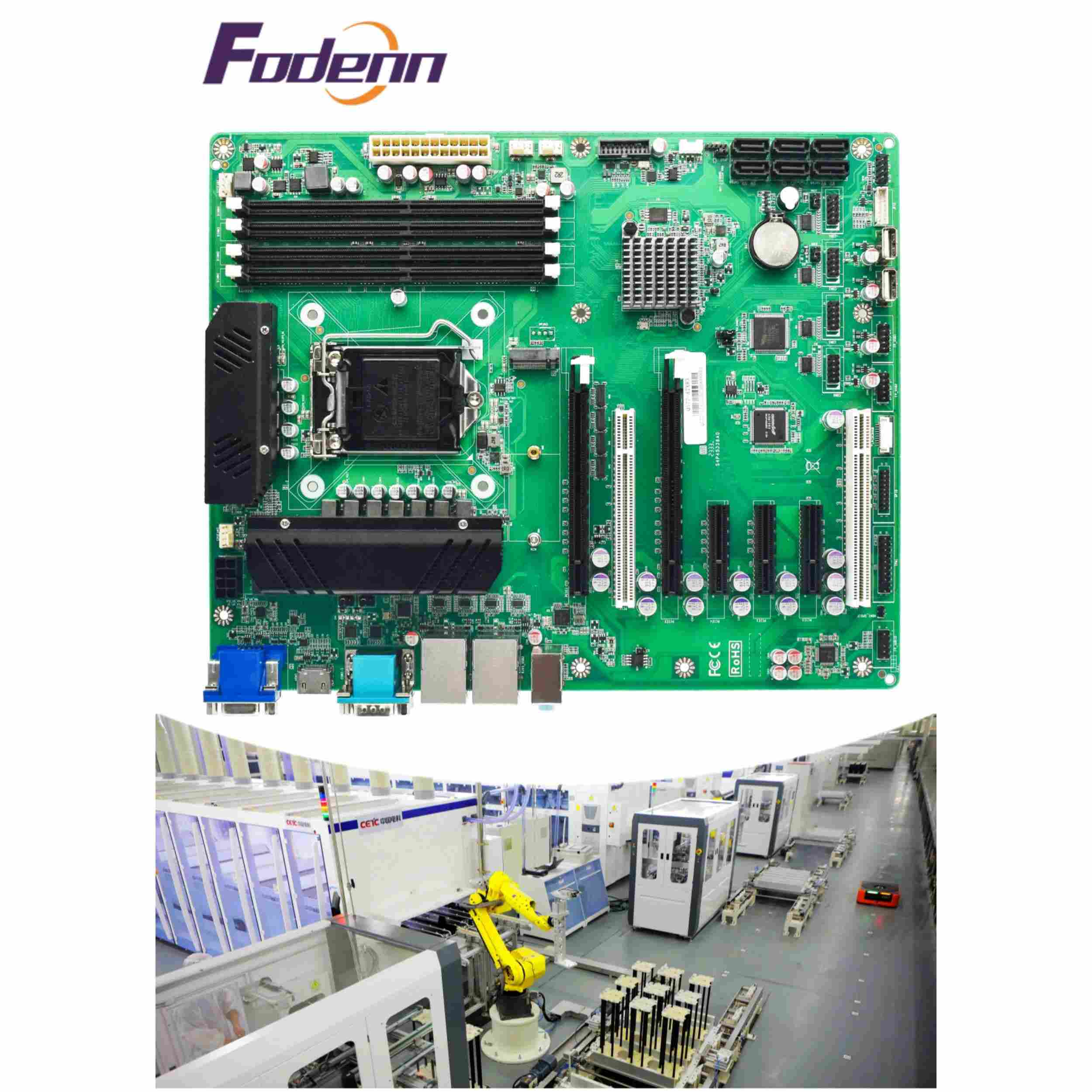

Industrial motherboards are dedicated motherboards designed for industrial applications, capable of withstanding extreme conditions such as high temperatures, continuous operation, and exposure to dust and humidity. It is often used in a variety of industrial equipment in the fields of manufacturing, automation, medical, defense, and energy.

- High reliability: It uses high-quality components and materials, and has been rigorously tested and verified to ensure stable operation in harsh environments.

- Long life: The design life is usually longer than that of ordinary motherboards, which can meet the needs of long-term operation in industrial scenarios.

- Anti-interference: The design takes into account factors such as electromagnetic interference, vibration, and temperature fluctuations, and can resist external interference to ensure stable operation of the system.

- Versatility: It has rich interfaces and expansion capabilities to meet the needs of different industrial application scenarios.

- Customization: It can be customized and developed according to the personalized needs of customers to meet the requirements of various special applications. Fodenn supply Customized Industrial Motherboards solutions for difference application.

- Price: It is usually more expensive than consumer-grade motherboards because high-quality components are used and a unique support system is established to create special designs.

Compatibility with a Vast Software Ecosystem

One of the most significant advantages of x86 Single Board Computers is their compatibility with a vast and mature software ecosystem. The x86 architecture has been a dominant player in the computing industry for decades, resulting in large amount of software applications, libraries, and tools that are readily available for use. Fodenn's x86 SBCs leverage this extensive compatibility, allowing developers to tap into a wide range of operating systems, including popular choices like Windows and various distributions of Linux. This flexibility ensures that you can deploy existing software solutions with ease, reducing development time and effort. Whether your project requires specific software tools or needs to integrate with existing systems, Fodenn's x86 SBCs provide the necessary platform to streamline your development process.

Robust Performance and Processing Power

Embedded computing projects often demand high performance and processing power, especially when dealing with complex tasks such as data analysis, image processing, or running multiple applications simultaneously. x86 Architechture motherboards are equipped with powerful processors from reputable manufacturers like Intel and AMD. These processors offer a wide range of performance options, from low-power, energy-efficient solutions suitable for basic tasks to high-performance processors capable of handling intensive computations. This scalability ensures that you can select an x86 motherboard that aligns with the specific performance requirements of your project, providing the necessary power to execute tasks efficiently and effectively.

Familiarity and Ease of Development

For many developers and engineers, the x86 architecture is already familiar territory. The widespread use of x86 processors in personal computers and servers means that there is a large pool of professionals who possess the skills and knowledge to work with x86-based systems. Fodenn's x86 SBC motherboards capitalize on this familiarity, allowing developers to quickly adapt to the hardware platform and utilize their existing expertise. Additionally, Fodenn provides comprehensive documentation, technical support, and development tools, further simplifying the development process. This enables you to focus on creating innovative solutions for your project, leveraging the extensive resources available for x86 development.

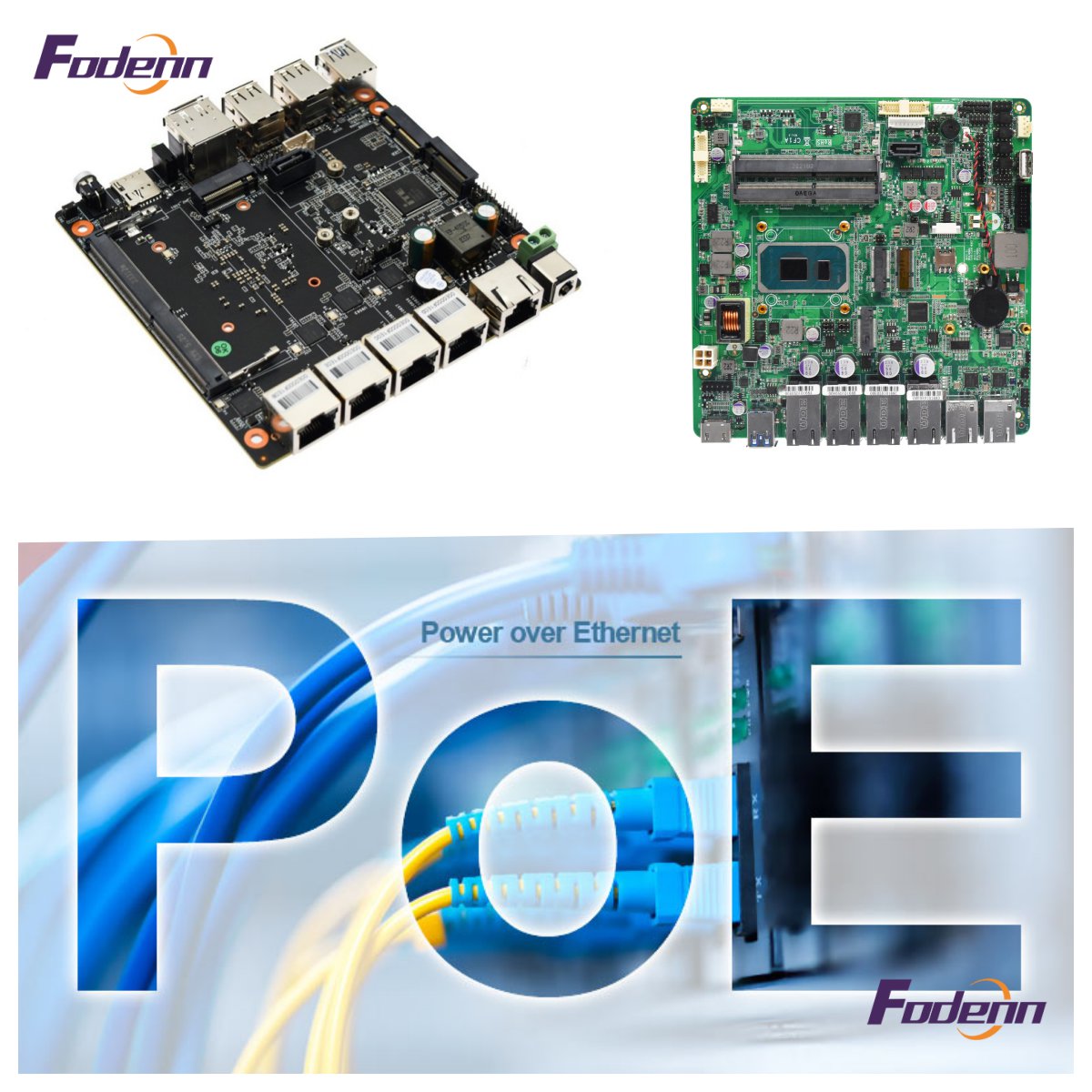

Wide Range of I/O Options and Expandability

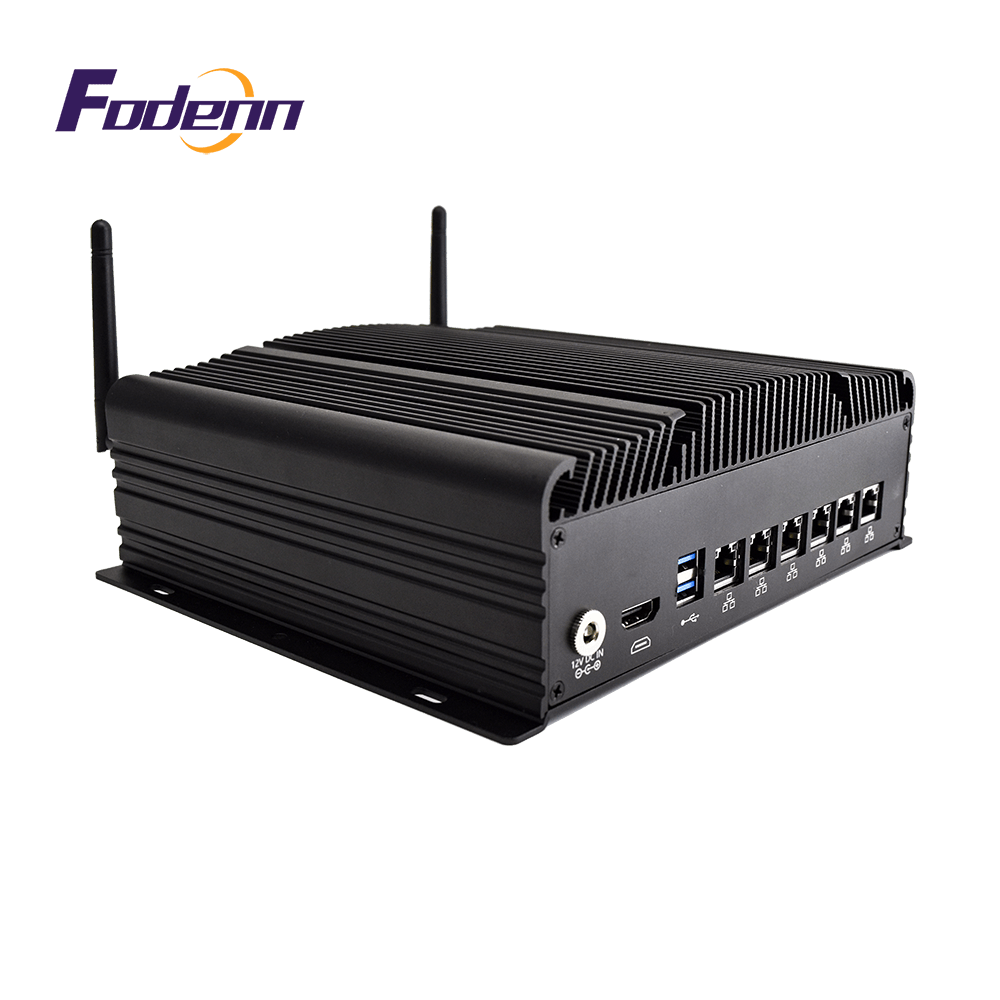

x86 SBCs typically come equipped with a diverse array of input/output (I/O) options, providing ample opportunities for connectivity and integration with various peripherals and devices. Fodenn's x86 SBCs are no exception, offering a rich set of I/O interfaces to meet the unique requirements of your project. From USB ports and HDMI for multimedia applications to serial ports, parallel ports, and GPIO pins for industrial control and data acquisition, Fodenn's boards provide the flexibility to connect a wide range of devices. Moreover, the expandability of board ensures that your x86 SBC can evolve alongside your project, accommodating future enhancements and upgrades without the need for complete system overhauls.

Real-Time Performance Capabilities

In embedded computing projects where real-time performance is critical, such as in industrial automation or medical equipment, x86 SBCs can deliver the necessary responsiveness. Fodenn's x86 SBCs are designed with real-time performance in mind, supporting real-time operating systems (RTOS) and providing the ability to prioritize tasks and manage resources effectively. This ensures that time-sensitive operations are executed within strict deadlines, maintaining the reliability and accuracy required for applications that demand precise control, accurate data processing, and timely decision-making. By choosing Fodenn's x86 SBCs, you can have confidence in the system's ability to meet the demanding real-time requirements of your project.

Established Reliability and Longevity

The x86 architecture has a proven track record of reliability and longevity in various computing environments. Fodenn's x86 SBCs are built with high-quality components and undergo rigorous testing to ensure their durability and stability. This reliability is crucial for embedded computing projects that often operate in harsh or challenging conditions, where system failures can have significant consequences. Furthermore, the longevity of the x86 architecture means that you can expect a longer product lifecycle for your x86 SBC, reducing the need for frequent hardware replacements and providing a stable platform for your project over the long term. Fodenn's commitment to quality and reliability ensures that their x86 SBCs are designed to withstand the test of time and continue to perform reliably throughout the life of your project.

OEM Services and Customization

Fodenn's expertise extends beyond standard x86 SBC offerings, as they provide comprehensive OEM services and customization options. This means that you can work closely with Fodenn to tailor their x86 SBCs to your specific project requirements. Whether you need modifications to the hardware design, custom firmware development, or integration with unique peripherals, Fodenn's team can collaborate with you to create a customized solution that perfectly fits your needs. This level of customization ensures that your x86 SBC is optimized for your project, maximizing performance, efficiency, and compatibility with your existing systems and workflows.

In conclusion, choosing an x86 Single Board Computer from Fodenn for your next embedded computing project offers numerous benefits. The compatibility with a vast software ecosystem, robust performance, familiarity for developers, wide range of I/O options, real-time performance capabilities, established reliability, and OEM services make Fodenn's x86 motherboards a strong contender for a wide variety of applications. Unlock the potential for innovation and success in your embedded computing endeavors.

Read More