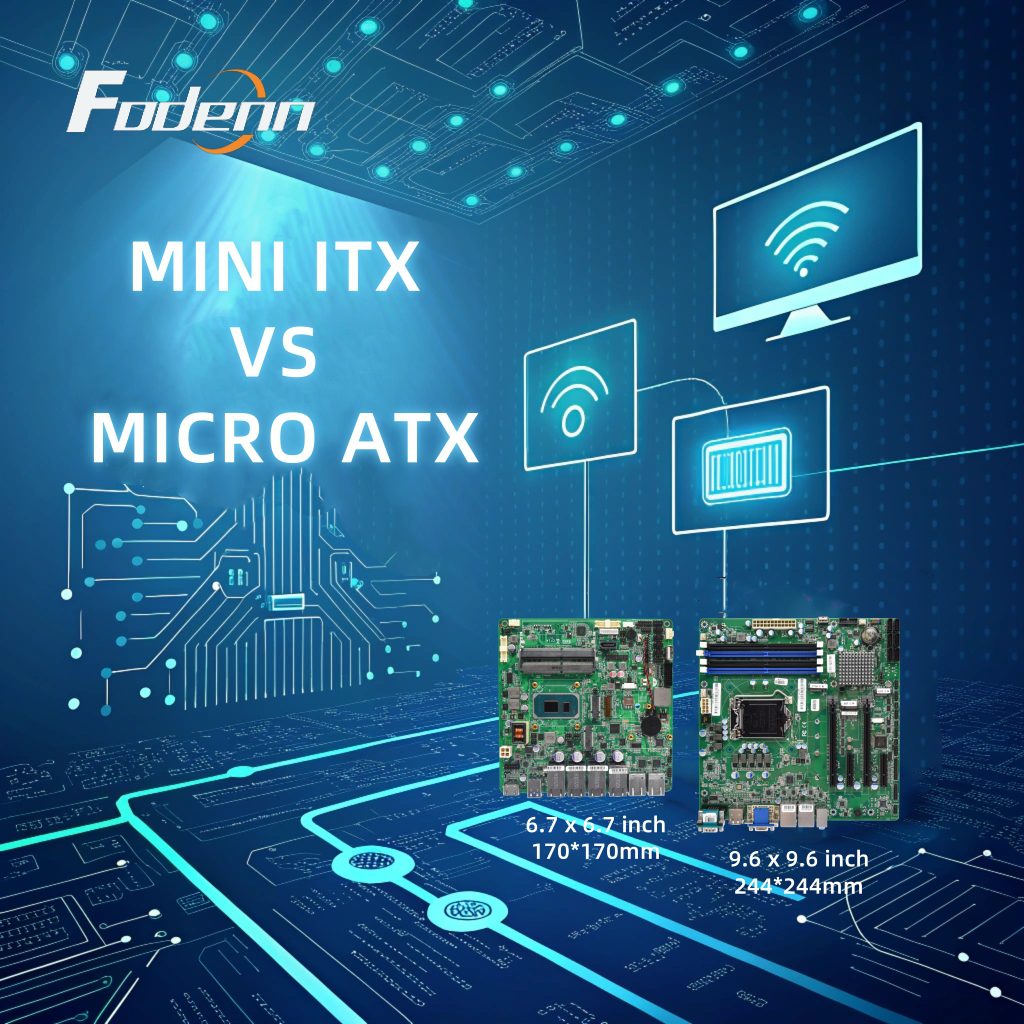

Selecting Suitable Industrial Motherboards via MINI-ITX vs. Micro ATX

Nov 29, 2024

Industrial PCs, once known as industrial computers, embedded computers, are often misconceived as devices exclusive to manufacturing devices. However, their applications extend far beyond the factory floor. Industrial computers are integrated into a variety of everyday technologies, such as ATMs in financial institutions, POS systems in convenience retail stores, and access control gates in MRT stations. It's no overstatement to say that "Industrial PCs are all around you." Given their broad application, the functions and specifications of Industrial PCs can vary slightly depending on the specific use case. For instance, the requirements for ATMs and POS systems are quite distinct. Consequently, IPC manufacturers must tailor their offerings to meet the diverse needs of different scenarios by providing industrial motherboards in various sizes and specifications.

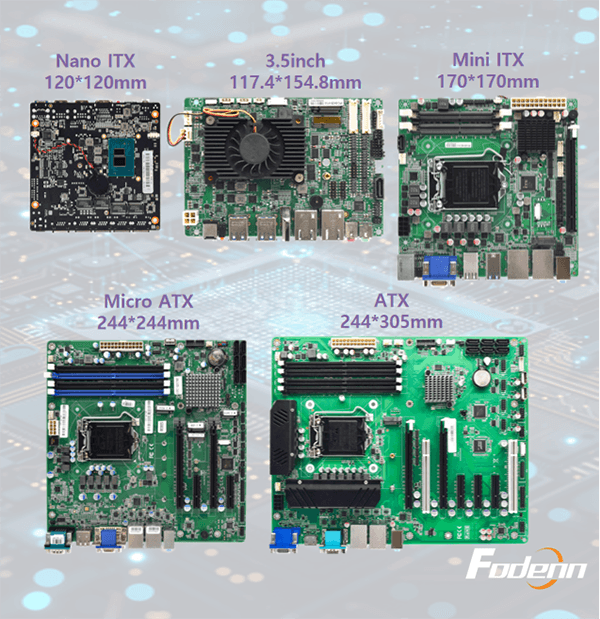

Industrial motherboards are central to the construction of industrial automation systems, serving as the link between a range of industrial equipment, sensors, and actuators. Their stability, reliability, and expandability are essential for the smooth operation of these systems. Developing a motherboard from the ground up is a lengthy process. To align with product launch timelines, the market has distilled the most common requirements and established three standard motherboard sizes: MINI ITX, Micro ATX, and ATX. This allows system integrators and end-users across industries to select the appropriate specifications for their needs and build customized systems. MINI-ITX and Micro ATX motherboards, as embodiments of miniaturization and performance, are extensively utilized in intelligent and automated equipment.

Overview of Industrial motherboard specifications

1. Motherboard size: MINI ITX motherboards are known for their extremely small size (170mm x 170mm), which is very suitable for space-constrained application scenarios.The size of Micro ATX motherboards (244mm x 244mm) is slightly larger than MINI-ITX, but still maintains good space efficiency.

2. Expansion capability: MINI-ITX motherboards usually provide fewer expansion slots, usually only one PCIe slot, which limits their expansion capabilities, especially in industrial applications that require multiple GPUs or other high-speed expansion cards, but are sufficient to meet basic industrial needs. Micro ATX motherboards offer more expansion slots, including additional PCIe and PCI slots to support more industrial expansion cards. They can provide more PCIe slots and other expansion options, which enables them to support more peripherals and higher-performance GPUs. This is very important for application scenarios that require complex computing or graphics processing, such as traffic light control equipment or medical action control equipment

Performance and Scalability

1. CPU Support:

MINI-ITX motherboards, due to their extremely small size (170mm x 170mm), are usually equipped with ultra-low-power x86 processors, which are often soldered on the motherboard and cooled with heat sinks instead of fans. For example, some industrial-grade MINI-ITX motherboards may use low-power CPUs from the Intel Atom series, Intel Alder Lake, Intel Tiger Lake, or Celeron/Pentium series.

Micro ATX motherboards (244mm x 244mm) have more space to accommodate higher-performance CPUs, including processors with higher thermal design power (TDP). For example, they can support processors from the Intel Core i7/i5/i3 series or AMD Ryzen series, which are usually equipped with more powerful multi-core performance and higher power consumption.

2. Memory support: Both motherboards support DDR3 / DDR4 / DDR5 memory, but Micro ATX motherboards usually support higher maximum memory capacity.

3. Storage interface: Both provide SATA interfaces, but Micro ATX motherboards may provide more SATA interfaces to support more storage devices.

4. Expansion slots: MINI-ITX motherboards usually provide fewer PCIe slots, while Micro ATX motherboards provide more PCIe and PCI slots.

I/O Interface and Connectivity

1. Rear I/O Interface: The rear I/O interface of MINI-ITX motherboards is more limited, but it is enough to meet basic needs. Micro ATX motherboards provide more USB ports, video output ports and other I/O interfaces.

2. Internal I/O Interfaces: Both offer front panel connections and internal USB expansion, but Micro ATX motherboards offer more options.

3. Network Connections: Both have integrated network cards, but Micro ATX motherboards may offer higher-level network connection options, such as dual network card support.

4. Audio Interfaces: Both have integrated sound cards, but Micro ATX motherboards may offer more advanced audio interfaces.

Heat Dissipation and Layout

1. Heat Dissipation Solutions:

Due to the compact design of MINI-ITX motherboards, they face greater challenges in heat dissipation, which may affect the choice of CPU because the power consumption and heat dissipation requirements of the processor need to be considered. In some extreme environments, such as automobiles or outdoor equipment, MINI-ITX motherboards may require specially designed CPUs to meet temperature resistance requirements.

Micro ATX motherboards usually have better heat dissipation designs due to more space, including larger heat sinks and more fans, which allows them to use higher power CPUs while keeping the system running stably.

2. Internal layout:

The internal layout of both motherboards needs to consider airflow management and cable management, but the Micro ATX motherboard has a more flexible layout due to its larger space. Whether it is a MINI-ITX or Micro ATX motherboard, they need to follow specific industrial standards to ensure compatibility with other hardware components. This means that despite the differences in size and performance, they can both run similar operating systems and software

Uses and applicable scenarios

1. MINI-ITX motherboards are suitable for space-constrained applications such as small HTPCs, home servers, and embedded systems.

2. Micro ATX motherboards are applicable scenarios: Suitable for applications that require more expansion, such as small and medium-sized tower cases, traffic light control equipment, medical action control equipment, and workstations.

Both industrial motherboards are widely used in industrial automation and embedded systems, although the specific application scenarios and requirements may vary. For example, MINI-ITX may be more suitable for space-constrained occasions, while Micro ATX may be more suitable for applications that require more expansion and more powerful computing power. Both MINI-ITX and Micro ATX motherboards emphasize long-term availability and a stable supply chain, which is essential for industrial systems that require long-term operation and maintenance. This requires that the CPUs they use must also have long-term supply and support

Cost and Value

1. Price comparison: MINI-ITX motherboards are usually cheaper and suitable for projects with limited budgets. Micro ATX motherboards are slightly more expensive, but provide more functions and expandability.

2. Balance between performance and cost: When choosing a motherboard, you need to balance performance and cost based on the specific needs and budget of the project.

Market Trends and Future Outlook

1. Market demand: With the development of industrial automation and the Internet of Things, the market demand for miniaturized motherboards continues to grow.

2. Technological development: In the future, motherboard technology may develop towards higher integration, stronger performance and better energy efficiency.

MINI-ITX and Micro ATX motherboards each have their own advantages in diverse industry market. MINI-ITX motherboards are suitable for space-constrained and budget-limited applications with their small size and lower cost, while Micro ATX motherboards are suitable for applications that require more functions and expansion with their better expandability and performance. Choosing the most suitable motherboard needs to be determined based on the specific needs and budget of the project. Discover how Fodenn can tailor industrial motherboards to your specific needs. Contact us today!

Read More