What Drives Custom Motherboard Market Growth?

Dec 09, 2024

In recent years, the customized motherboard market has shown a significant growth trend. With the continuous advancement of technology, users' demands for motherboards have become increasingly diversified, especially in the fields of high-performance embedded computing, industrial control, and embedded computer systems. According to the 2023 industry report, the industrial computer motherboard industry is developing towards high-end, intelligence and personalization, and the market size is gradually expanding.

Analysis of Customized Motherboard Demand

1. Growing demand for customized motherboards: With the development of technology and the increase in demand for specific industries, the demand for customized motherboards is growing. These motherboards are often used in specific application scenarios, such as industrial automation control, machine vision,financial medical equipment, cloud computing platform terminals, multimedia advertising machines, security monitoring network systems, high-end games, gambling lottery game machines, and professional computing etc.

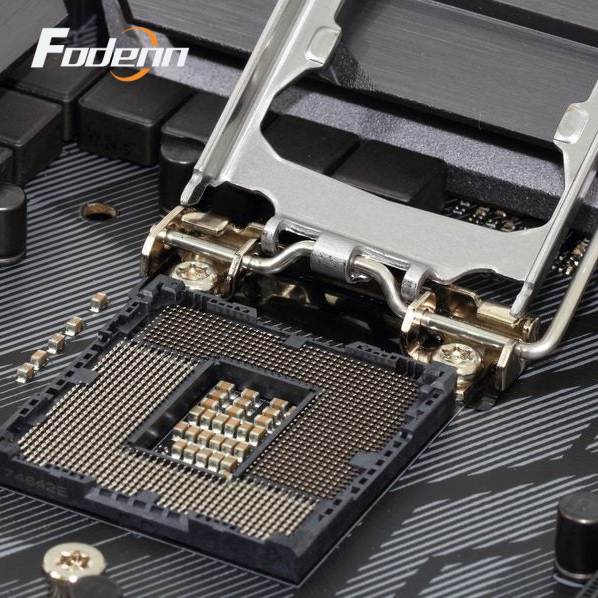

2. Diversity of technical specifications: Users' demand for customized motherboards is becoming more and more diverse, including different processor platform support, memory specifications, storage interfaces, expansion slots, and other specific I/O requirements. For example, some users may need support for a specific model of CPU like Intel 12th Gen Alder Lake N95 N100 N200 Motherboards, or require a specific I/O port configuration to meet their application needs.

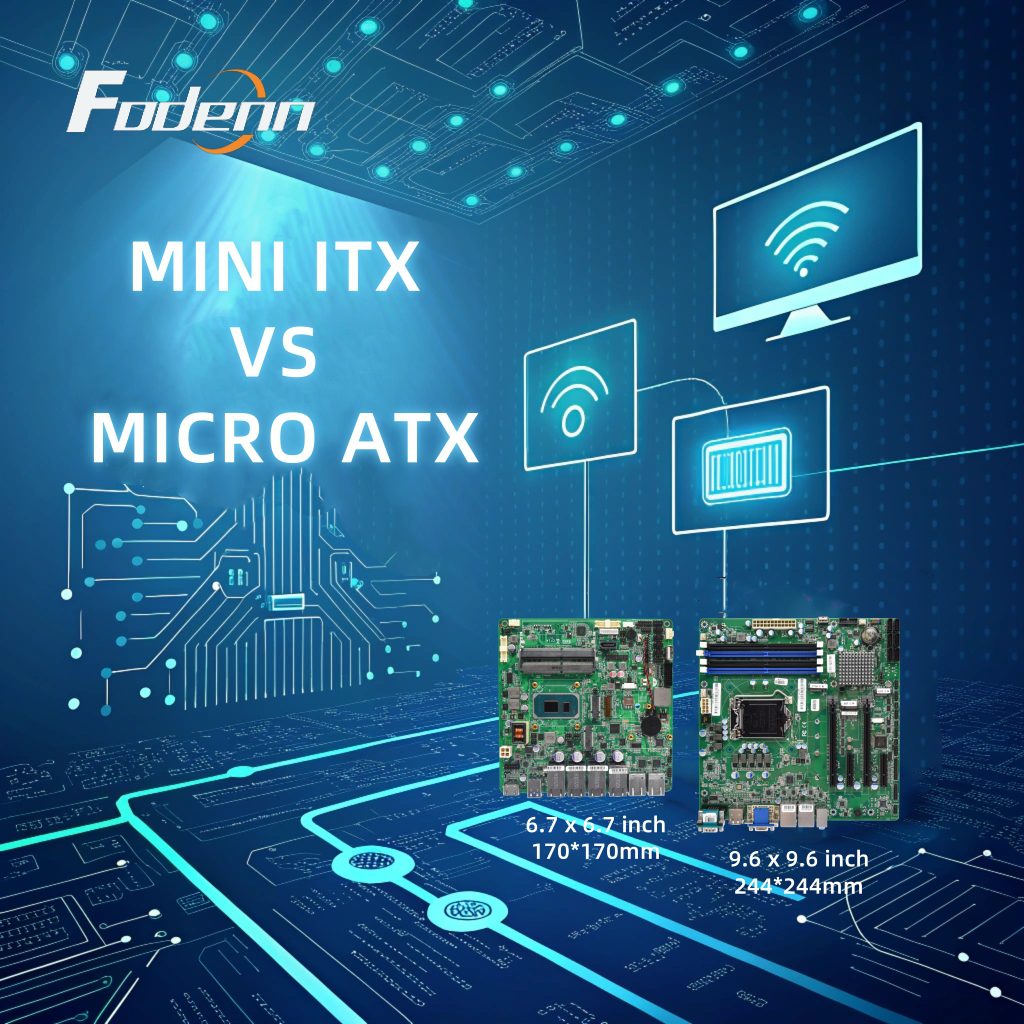

3. The popularity of mini ITX motherboards: Mini ITX motherboards are popular for their small size and high performance, especially when building small or high-performance computing systems. These motherboards are often used in small PCs / Mini PCs, embedded systems, and home servers.

4. Demand for integrated technology: Users are increasingly inclined to motherboards that integrate advanced technologies, such as POE, WiFi 6E, PCIe 4.0 and 5.0 support, etc. These technologies can provide faster data transmission speeds and better wireless connection performance.

5. Emphasis on cooling solutions: As CPU performance increases, cooling becomes an important consideration. Some custom motherboards fanless computers begin to integrate or recommend advanced cooling solutions, such as water cooling systems, to keep the system running stably.

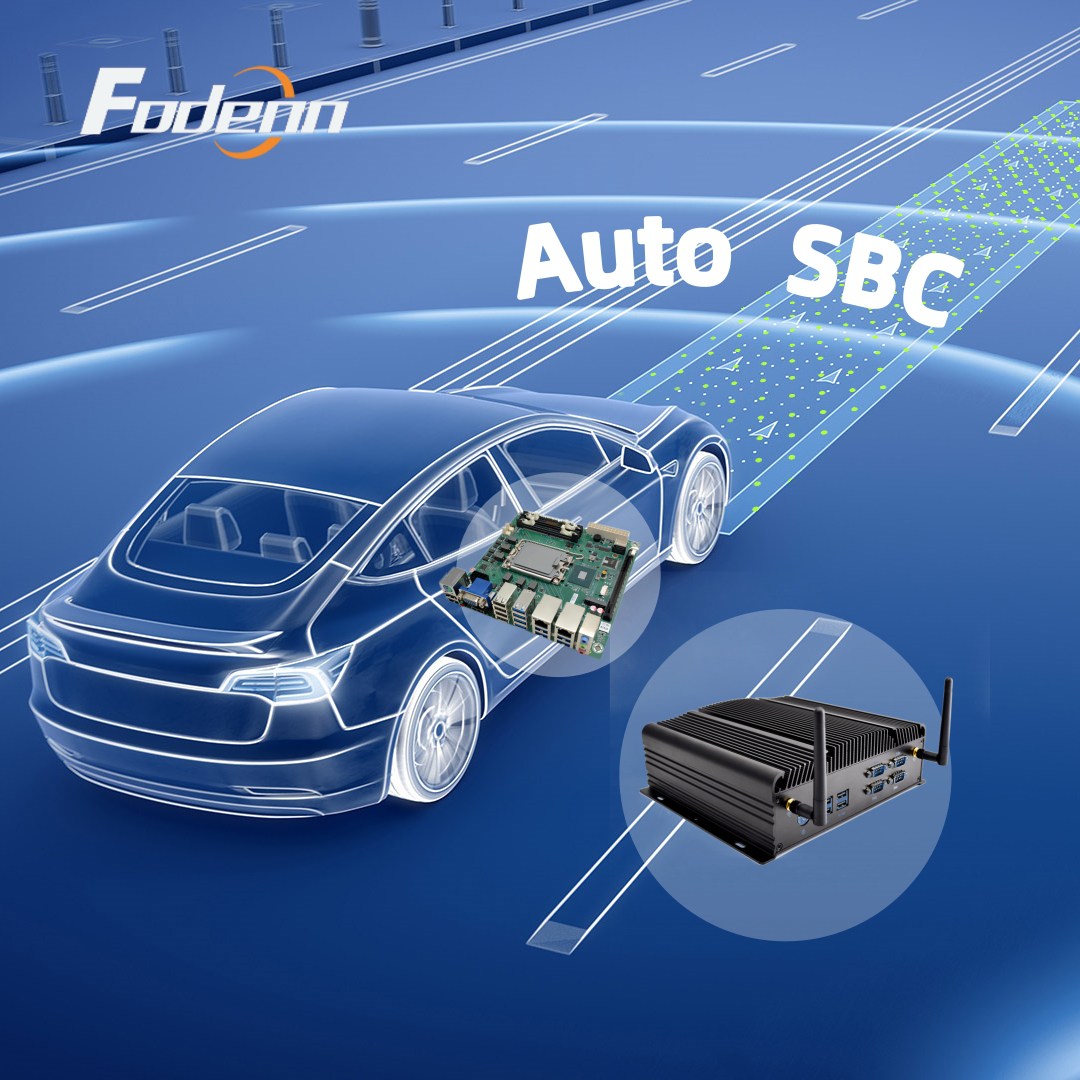

6. Stable demand in the industrial and embedded markets: The demand for custom motherboards in the industrial and embedded markets remains stable, and these motherboards are often required to meet specific durability, reliability, and long-term availability requirements.

7. Price sensitivity: Although custom motherboards are usually more expensive, there are still price-sensitive user groups in the market. They may look for cost-effective custom motherboard options, or semi-customize on the basis of standard products to reduce costs.

Fodenn's comprehensive customization service

As a industrial motherboard and embedded computer manufacturer with 15 years of R&D and production experience, Fodenn provides comprehensive customization services in response to market demand. Fodenn has taken the following measures in the technical innovation of customized motherboards:

Rapid response to customer customization needs: Fodenn is able to provide standard or customized industrial motherboards and embedded computers product to quickly respond to customer needs, from product conceptualization to on-time delivery

Cost control: Through supply chain management, Fodenn helps customers save costs, avoids additional processes and unnecessary specification costs, and achieves accurate budget control and evaluation

Comprehensive customization services: Fodenn provides a range of services from complete equipment structure customization to motherboard customization, including system assembly, operating system installation, system testing, customized environment and EMC testing, etc.

R&D advantages: Fodenn has professional R&D capabilities and rich experience, and can provide customers with customized solutions for various special computer motherboards and complete machines.

Fast product customization cycle: Fodenn can complete the customization of customized board products within 45 working days, and the customization of complete machine products can be completed within 60 days

Design and development: Fodenn conducts engineering prototype (EVT), hardware/BIOS debugging, power supply, clock check, predictive testing; verification engineering prototype (VE), BFT, RT, ST, CT testing, and provides VE reports.

Feasibility study: Fodenn's hardware, BIOS, product engineering, verification engineering, and procurement teams will evaluate all relevant issues of the project and provide an evaluation report.

R&D and production capabilities: Fodenn has a 20,000 square meter R&D center and production lines, including 8 automatic DIP lines, 12 automatic SMT lines, 6 automatic packaging lines, 6 test lines and 2 automatic aging lines

Cooperation with Intel: As a member of the Intel IoT Solutions Alliance, Fodenn focuses on Intel product solutions and provides more than 1,000 solutions to meet the various needs of customers

Market recognition: Fodenn has been recognized for technological innovation and market strategy, such as winning the 2023 "Market Breakthrough Award"

The customized motherboard market is in rapid development, and technological progress and diversification of market demand have driven this trend. With its rich experience and comprehensive customized services, Fodenn can effectively respond to market challenges and meet the personalized needs of customers. In the future, Fodenn will continue to focus on technological innovation and service improvement to maintain its competitive advantage in the industry.

Find the Customized Solutions You Need for Your Next ProjectHere at Fodenn, we deliver custom solutions to a wide range of industries, from industrial manufacturing and financial healthcare to retail self-service, transportation, gambling, cloud network construction and etc. To find the custom solutions you need for your next project, browse our web or reach out to our team directly to learn more.

Read More