Why are PCIe slots essential for industrial computing applications?

Jan 24, 2025

In the realm of industrial computing, the performance and reliability of systems are paramount. Industrial motherboards and industrial PCs (IPCs) are designed to meet the rigorous demands of industrial environments, where high-speed data transfer, real-time processing, and robust connectivity are essential. One of the key technologies that enable these capabilities is the PCIe (Peripheral Component Interconnect Express) interface. This article will explore the importance of PCIe interfaces in industrial motherboards and IPCs, their features, and the benefits they offer.

PCIe is a high-speed serial computer expansion bus standard used for attaching hardware devices to a computer. It is the successor to the older PCI and PCI-X bus standards and has become the dominant interface for connecting a wide range of peripherals, including graphics cards, network cards, storage devices, and more. PCIe offers several advantages over its predecessors, including higher data transfer rates, improved power management, and greater flexibility.

Key Features of PCIe in Industrial PC

High-Speed Data Transfer

PCIe supports much higher data transfer rates compared to traditional PCI and PCI-X. The latest PCIe 4.0 and 5.0 standards offer data transfer rates of up to 64 Gbps and 128 Gbps, respectively, making them ideal for data-intensive applications such as high-resolution video processing, large-scale data analytics, and real-time control systems.

Scalability

PCIe is highly scalable, allowing for multiple lanes (x1, x2, x4, x8, x16, etc.) to be used depending on the bandwidth requirements of the connected device. This scalability ensures that the interface can adapt to the needs of various peripherals, from low-bandwidth sensors to high-bandwidth graphics cards.

Power Management

PCIe includes advanced power management features that allow devices to enter low-power states when not in use, reducing overall power consumption and improving energy efficiency. This is particularly important in industrial settings where power usage and heat generation need to be minimized.

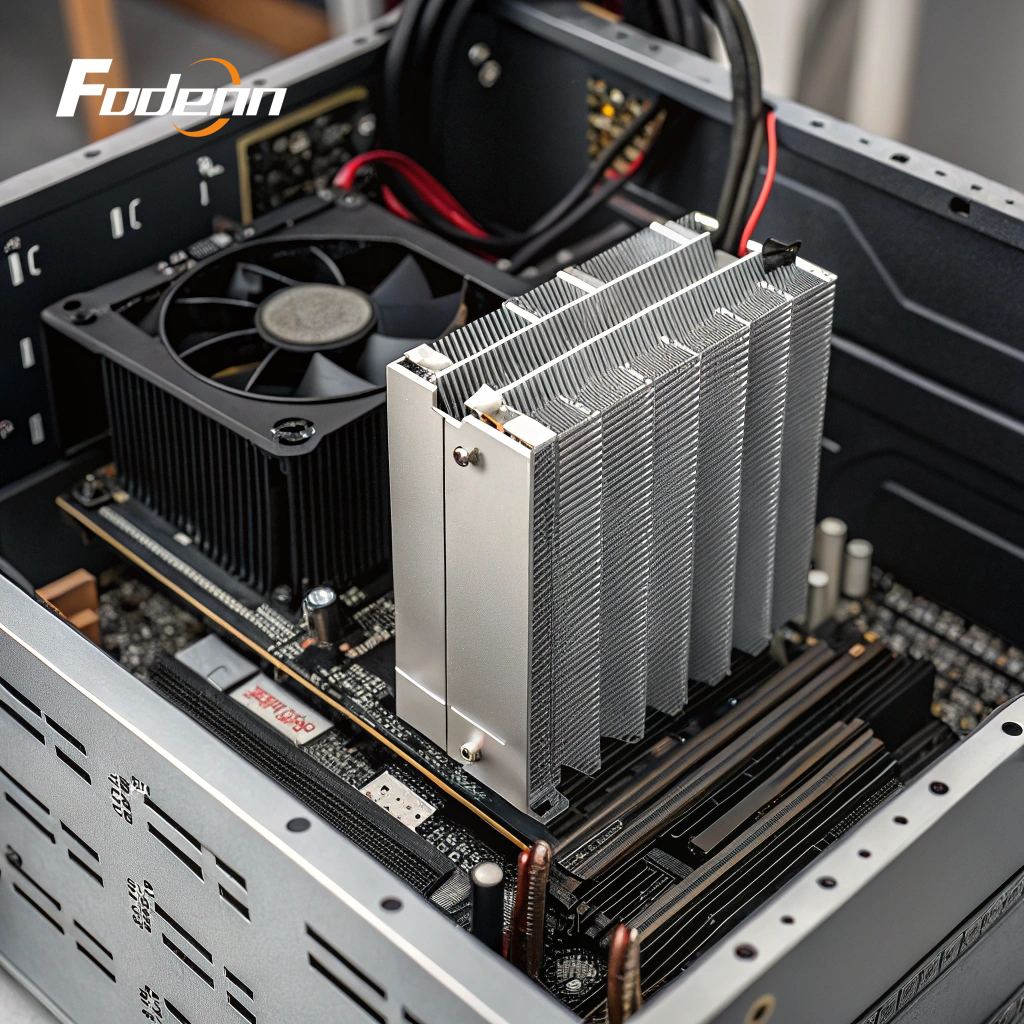

PCIe in Industrial Motherboards

Industrial application motherboards are designed to provide a robust and reliable foundation for industrial computing systems. They often include multiple PCIe slots to support a wide range of peripherals and expansion cards,such as IPC-Q477 PCIE x16 Industrial Embedded Motherboard. These slots are essential for adding functionality to the system, such as:

High-performance graphics cards are often required for applications such as machine vision, where high-resolution images need to be processed in real-time. PCIe slots provide the necessary bandwidth to support these powerful graphics cards, ensuring smooth and efficient operation.

Industrial environments often require high-speed, reliable network connectivity. PCIe network cards can provide gigabit Ethernet or even 10 Gbps Ethernet connections, enabling fast data transfer and remote monitoring and control.

Data acquisition (DAQ) cards are used to collect and process analog and digital signals from various sensors and devices. PCIe DAQ cards offer high-speed data transfer and real-time processing capabilities, making them ideal for applications such as process control and condition monitoring.

High-speed storage devices, such as SSDs, can be connected via PCIe to provide fast read and write speeds, reducing data transfer times and improving system performance.

Industrial applications may require specialized expansion cards for tasks such as motion control, digital I/O, and analog I/O. PCIe slots provide the flexibility to add these cards as needed, ensuring that the system can be tailored to meet specific requirements.

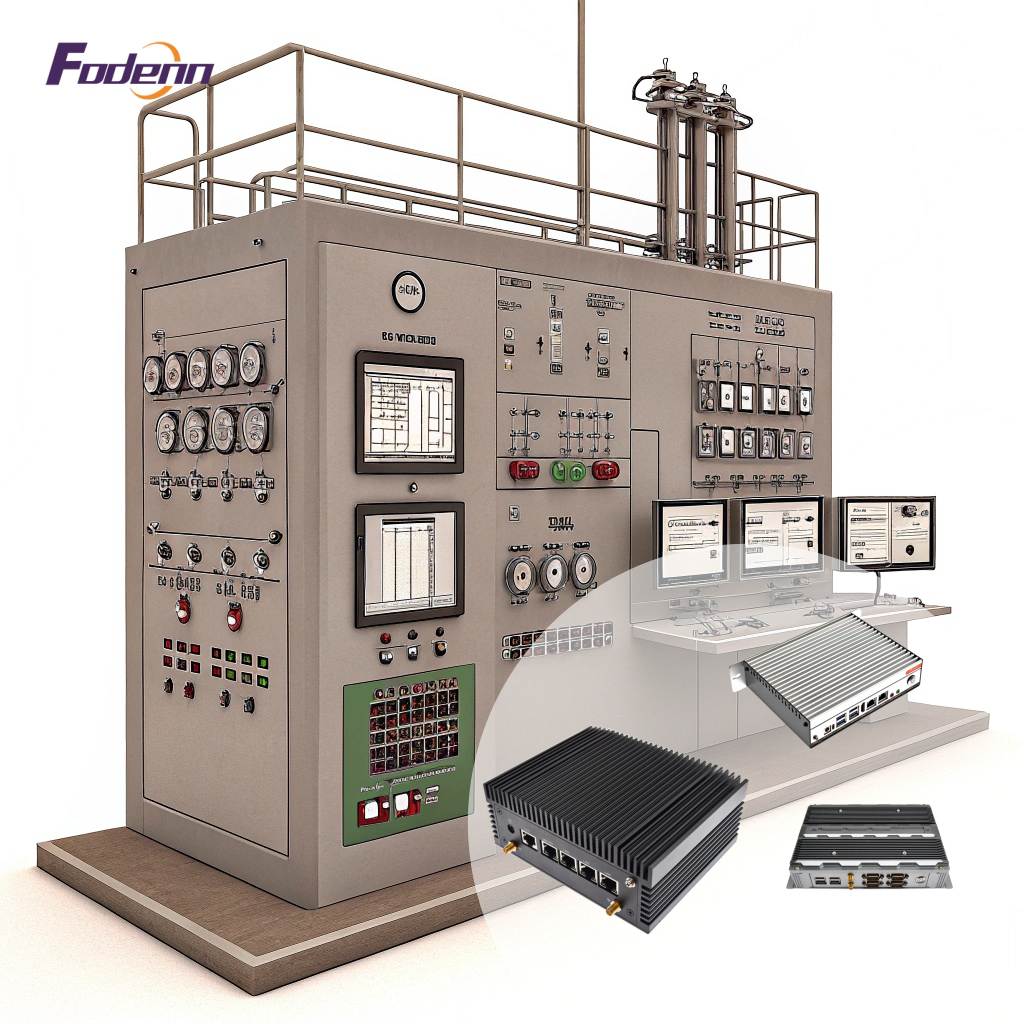

PCIe in Industrial PCs (IPCs)

Industrial PCs (IPCs) are pre-configured systems designed for specific industrial applications. They often include integrated PCIe devices and expansion slots to support a wide range of peripherals.

Some common uses of PCIe in IPCs include:

Integrated Graphics and Networking:

Many industrial-grade computers come with integrated PCIe graphics and network cards, providing high-performance capabilities out of the box. These integrated devices ensure that the system is ready for deployment without the need for additional configuration,such as IPC-AC500 custom Embedded Mini Computers.

Expansion Capabilities:

Despite being pre-configured, IPCs often include spare PCIe slots for future expansion. This allows users to add additional functionality as their needs grow, such as upgrading to a faster network card or adding a high-resolution display.

Customization:

PCIe slots enable customization of IPCs to meet specific application requirements. For example, an IPC used in a manufacturing setting may require a PCIe motion control card, while one used in a data center may need additional storage or network capabilities.

Benefits of PCIe in Industrial Applications

Performance:

The high-speed data transfer capabilities of PCIe ensure that industrial systems can process large amounts of data quickly and efficiently, improving overall system performance and reducing latency.

Reliability:

PCIe's robust design and advanced error detection and correction features ensure reliable data transfer, reducing the risk of data corruption and system failures.

Flexibility:

The scalability and backward compatibility of PCIe provide flexibility in system design and upgrades, ensuring that investments in hardware are future-proof and can be adapted to changing requirements.

Energy Efficiency:

Advanced power management features of PCIe help reduce power consumption and heat generation, improving the energy efficiency of industrial systems and reducing operating costs.

Integration:

PCIe's wide adoption and support for a variety of peripherals and expansion cards make it easy to integrate different devices and systems, ensuring seamless operation and compatibility.

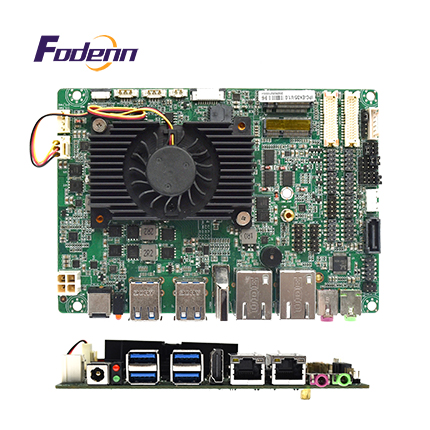

Fodenn's Industrial Motherboards and IPCs with PCIe

Fodenn, a leading industrial computer manufacturer, offers a range of industrial motherboards and IPCs equipped with advanced PCIe interfaces. Our solutions are designed to meet the demanding requirements of modern industrial applications, providing high-performance, reliable, and flexible computing platforms. Built using industrial-grade components, our systems are designed to withstand harsh environmental conditions, ensuring reliable operation in challenging industrial settings. Fodenn provides comprehensive technical support and documentation, ensuring that users can easily configure and deploy their systems.

PCIe interfaces play a crucial role in modern industrial computing, providing the high-speed data transfer, reliability, and flexibility needed for a wide range of applications. Fodenn's industrial motherboards and IPCs with advanced PCIe capabilities offer a robust and reliable solution for businesses looking to enhance their industrial computing infrastructure. Whether for data-intensive processing, real-time control, or high-speed networking, Fodenn's solutions ensure that your systems are equipped to meet the challenges of today's industrial landscape. Contact Fodenn for more information or to discuss your specific requirements.

Read More